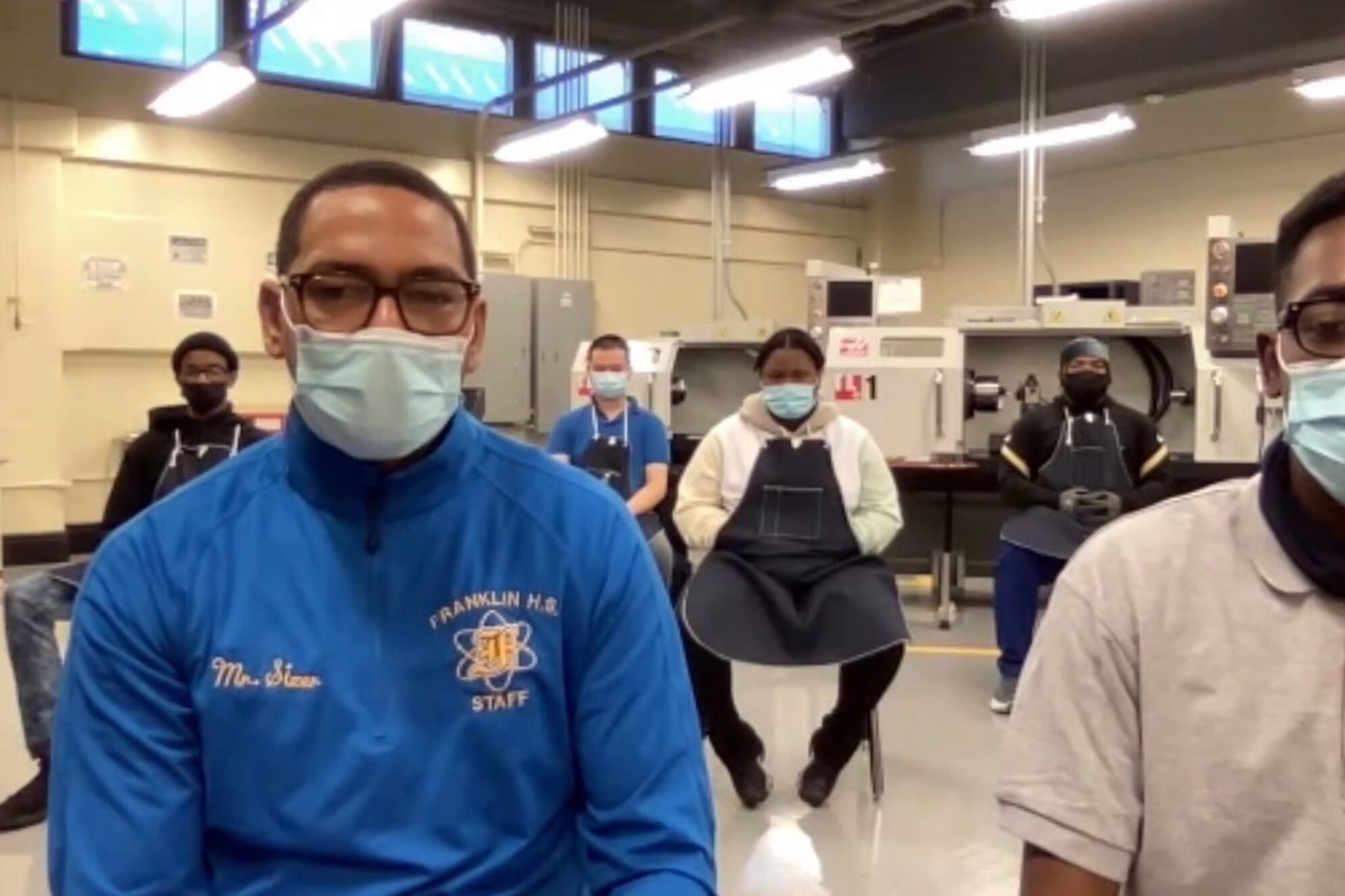

Ronald Sizer teaches precision machine tool technology at Benjamin Franklin High School. It’s the only program of its kind in the Philadelphia district, and it involves students learning to make tools, operate heavy machinery, and read blueprints.

“My father had me machining, welding, and grinding parts by 12 years old. As I became a man, machining was the only industry I considered,” said Sizer, the son of a machinist father and a mother who became the first Black nurse at Abington Hospital.

Sizer’s students are among the roughly 6,000 in the Philadelphia school system enrolled in career or technical education programs, or CTE, across more than 40 occupational areas — from auto repair to culinary arts. Such programs enable students to earn an industry-recognized credential or certificate along with their high school diploma.

February is CTE Month, which raises awareness of the role that career-oriented training has in education.

Before he started teaching, Sizer worked as a machinist at Marmetal Industries. The company’s owner saw his potential and sent him to the National Center of Defense Manufacturing and Machining for training. There, he received numerous certifications allowing him to work at high levels in the machine industry.

“I came back and worked on all Navy contracts, where I made parts for submarines, aircraft carriers, and more,” he said.

Sizer ended up at American Manufacturing & Engineering, making parts for the medical field such as bone files, bone replacements, and more. He also worked in the aerospace field, making parts for planes, helicopters, and even NASA.

Warren Crosby, a senior at Benjamin Franklin, enrolled in the precision machining program when he was a sophomore.

“In the ninth grade, I had no goal of what I wanted to do in life,” said Crosby said. “I talked to Sizer about precision machining. He told me all the benefits and what you would have to do to succeed.” After a year of learning, he got a summer job at Amazon and was quickly promoted. When he graduates high school in June, Crosby will transition into a full-time job with the Naval Foundry and Propeller Center.

Sizer, who spoke recently with Chalkbeat, said: “Giving the students respect and receiving it in return is an amazing feeling. When there is mutual respect, teaching and learning are easy for us both. The most gratifying feeling is seeing your graduates succeed financially after high school.”

This interview has been lightly edited for length and clarity.

What was your biggest misconception that you initially brought to teaching?

The biggest misconception was that I would be able to teach machining without providing refreshers and lessons in advanced geometry and trigonometry – two areas that are important in precision machining. That’s when I realized I could use my class to help improve and, in some cases, advance the math skills of our students.

What has been your biggest hurdle returning to in-person learning?

Being a CTE teacher, the biggest hurdle from coming back after a year and a half was the equipment. Knowing my machines had been sitting for so long without daily, weekly, and monthly maintenance, I had to figure out which machines rusted out, which ones had to be serviced, and which ones no longer worked and had to be replaced. Teachers get a week to set up their classrooms and prepare for the return of the students. I spent that week servicing equipment that I could on-site and sending ones that I couldn’t to the manufacturer. Senior students came back and began learning machine maintenance immediately. Although it took a little longer to get the machine running due to the teaching part, seniors can now do monthly and weekly maintenance.

Describe what makes your teaching experience unique.

Teaching the machine shop gives me the opportunity to work backward, or as I like to say, in reverse. After learning the safety protocols and machine safety, students get to work right away on the machines. They start cutting and making projects on the machines and then learn the name of the tools they just used and the theory of the tool. If a drill breaks or a blade snaps, the student gets in the classroom and finds out why it broke and what should have been done during the operation. They are learning faster like this and remember everything taught. There are so many “aha” moments for students, who love working in the shop and making projects. When they hear the correct name or operation of the tool, their eyes light up.

Why teach machining at Ben Franklin?

I was taking my daughter to the high school fair at the convention center [about five years ago]. Since she was interested in cosmetology, we went straight to the CTE table. I looked through the programs offered in the district and asked a man named Charles why there was no CNC Machining program as I explained to him my background. I went on to say there aren’t many Black and brown folks with the skills and knowledge to manufacture parts. Charles grabbed a packet, opened it up, and showed me they did teach CNC at Ben Franklin High School and were looking for a teacher. After our conversation, he went on and on, saying he needed me to take over the program, and I thought this man was crazy. I did not even give it a second thought until a week later; there was an offer letter in my email. After thinking about it, speaking with my family about it, I realized if I want to make a change, this is my chance to pass down the skills that I learned from my father and all the skills learned on my journey to being a top CNC machinist. After years of being the only Black machinist in the shop, I knew that I could make the difference and help diversify the manufacturing field. I accepted the offer and haven’t looked back!

Tell us about a memorable time — good or bad — when contact with a student’s family changed your perspective or approach.

As a CTE teacher, we not only teach the trade, but we help students to get working papers, help them prepare for job interviews, show them how to search for a job, and teach students with a lot of the soft skills needed to act on the job site. I reached out to a parent one time to help the student complete his work permit application. But I soon learned that that student wanted a future for himself, and the parent had a separate agenda. This experience made me realize how important what I do is to make a difference in our neighborhoods and changing the mindset that is embedded in the minds of some parents. After speaking and working with the family, I was able to help the student become the breadwinner of the household, and he helped move his family out of the old neighborhood they grew up in.